Direct-Drive Mechanical Manual Operation

The 2W Wrangler Series Manual Head Gate is designed with a direct-drive mechanically operated lever which provide the operator with increased leverage and strength when actuating the head gate. This results in less effort required to maintain a secured locked position when processing cattle.

Wear Resistant, Greaseable, And Easily Serviceable Joints

This head gate has built in grease zerks for easy serviceability and maintenance intervals. A quick shot of grease in each of the joints provides an additional layer of corrosion resistance as well as lubricating the joints.

Laser Cut

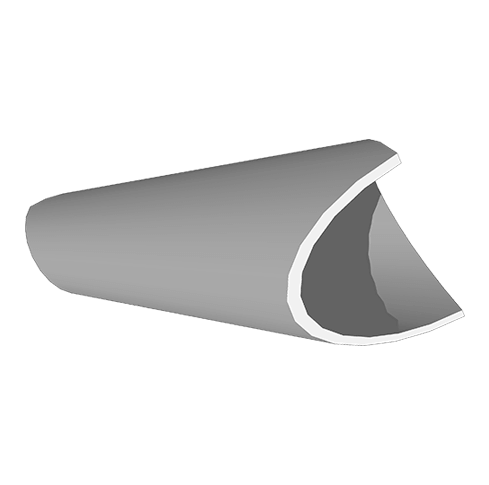

Steel Tube

2W utilizes Fiber Laser Technology to precision saddle cut high quality steel tube. The built-in software calculates the saddle cut ensuring a perfect fit when placed into the robotic welding fixture. This saddle cut provides vastly increased assembly strength over traditional “Pinch & Weld” style panels, whilst maintaining similar pricing for the end customer. In short, 2W patrons receive a higher durability product for the same price.